Author: Site Editor Publish Time: 2026-01-13 Origin: Site

Small batch CNC machining refers to the production of a limited number of precision parts using computer numerical control (CNC) technology. Unlike mass production, which focuses on very high volumes, small batch production typically ranges from a single prototype to several thousand units. This manufacturing approach is especially valuable for companies that require flexibility, fast turnaround, and consistent quality without committing to expensive tooling or molds.

For R&D projects, small batch CNC machining plays a critical role. During product development, designs are often revised multiple times. CNC machining allows engineers to quickly test functional prototypes, validate tolerances, and evaluate real-world performance using production-grade materials. Because CNC machines are digitally controlled, design changes can be implemented rapidly by updating CAD/CAM files, significantly reducing development cycles.

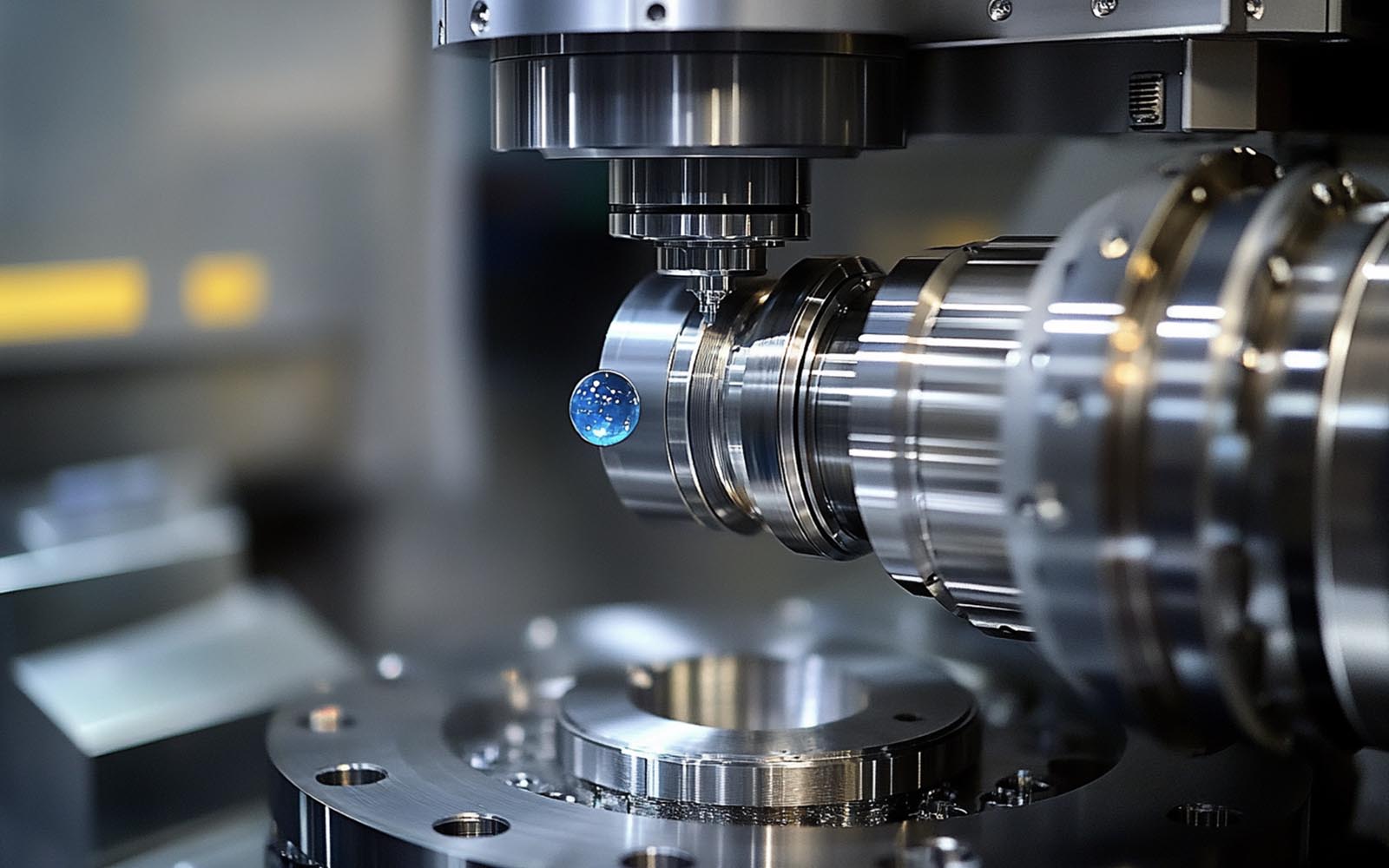

At Dongguan Hongxia Precision Machinery Co., Ltd., small batch CNC machining is supported by advanced 3-axis, 4-axis, and 5-axis equipment, enabling the production of complex geometries with micron-level accuracy. With nearly 20 years of experience and over 10,000 part types processed, the company is well positioned to support both early-stage R&D and scalable low-volume manufacturing.

A wide range of CNC processes can be applied to small batch machining, depending on part geometry, material, and functional requirements. The most common processes include CNC turning, CNC milling, CNC drilling, EDM machining, and multi-axis CNC machining.

CNC turning is ideal for cylindrical or axisymmetric components such as shafts, fasteners, and bushings. The workpiece rotates while a cutting tool removes material, ensuring excellent concentricity and surface consistency. This process is widely used in mechanical assemblies and industrial equipment.

CNC milling is one of the most versatile processes in small batch production. Using rotating cutting tools, milling machines can create complex shapes, pockets, slots, and contours. Multi-point cutting tools allow for precise control over surface finish and dimensional accuracy, making CNC milling suitable for electronic housings, enclosures, brackets, and structural components.

For parts requiring precise holes, CNC drilling provides excellent repeatability and positional accuracy. Advanced CNC setups also allow for reaming, tapping, and angled hole creation, which is essential in aerospace, medical, and precision mechanical applications.

EDM machining, including sinker EDM and wire EDM, is commonly used for hard metals or parts with intricate internal features. These non-contact processes use electrical discharges to remove material, making them ideal for mold inserts, dies, and components requiring extremely tight tolerances.

For highly complex parts, 5-axis CNC machining offers significant advantages. By allowing simultaneous movement along multiple axes, 5-axis machining reduces setup time, improves accuracy, and enables the production of geometries that are difficult or impossible with traditional 3-axis machines.

One of the key advantages of small batch CNC machining is material flexibility. Manufacturers can select from a wide range of metals and engineering plastics to match functional, mechanical, and environmental requirements.

Common metal materials include aluminum, stainless steel, brass, mild steel, alloy steel, and tool steel. Aluminum is particularly popular in small batch production due to its excellent machinability, lightweight properties, and corrosion resistance. Stainless steel is preferred when strength and corrosion resistance are critical, while brass is often chosen for its electrical conductivity and ease of machining.

Engineering plastics are also widely used, especially in R&D projects. ABS, nylon, PTFE, POM, polycarbonate, HDPE, and PEEK offer diverse properties such as chemical resistance, low friction, high strength, and thermal stability. These materials are frequently used in medical devices, electronics, automotive components, and industrial equipment.

Surface finishes further enhance part performance and appearance. As-machined finishes are suitable for parts requiring tight tolerances. Bead blasting improves surface uniformity and aesthetics, while anodizing provides corrosion and wear resistance for aluminum components. Powder coating adds durability and visual appeal but is typically used when dimensional precision is less critical.

By offering access to over 50 certified materials and multiple finishing options, Hongxia Precision ensures that each small batch production run meets both functional and aesthetic requirements.

Small batch CNC machining offers several strategic advantages, particularly for R&D-driven companies. First, it significantly reduces time to market. Engineers can move quickly from design to physical parts, enabling faster testing, validation, and iteration.

Second, it minimizes financial risk. Unlike injection molding or die casting, CNC machining does not require costly tooling. This makes small batch production ideal for startups, custom equipment manufacturers, and companies launching new products.

Third, CNC machining ensures consistent quality. Once a process is validated, parts can be reproduced with high repeatability, even across multiple batches. This is essential for R&D projects transitioning into pilot production or early commercialization.

Finally, small batch CNC machining supports scalability. Production volumes can easily increase from prototypes to tens of thousands of units without changing the manufacturing method. With flexible batch sizes ranging from 1 to 100,000+ units, Hongxia Precision supports customers throughout the entire product lifecycle.

Backed by strict quality control systems, including CMM inspection and triple inspection procedures, and supported by a responsive technical team available 24/7, the company delivers reliable, high-precision machining solutions that empower innovation and long-term success.